Services Overview

Pixus Technologies' services include customization, creative design, thermal simulation, signal integrity simulation/test, and more. Our expertise from specialization in backplane design to mechanical precision, to detailed knowledge of embedded systems gives us unique perspective to offer creative solutions.

Starting from the customer's requirement, Pixus delivers working, fully tested backplanes and chassis. Supported by Staff Systems Engineers (SSEs) in the field, our experienced design managers walk the customer through resolution of all issues related to CompactPCI, AdvancedTCA and OpenVPX compatibility. We can often recommend alternative approaches to critical design constraints.

Front Panel Customization and Assemblies

Front panels require precision design and manufacturing to ensure optimal performance, reliability, and EMC protection. Services for the front panels include custom design, stamping/milling, painting/silkscreening, assembly and single part number ordering. Contact Pixus for custom handle/panel services.

"Modified Standards" and Customization

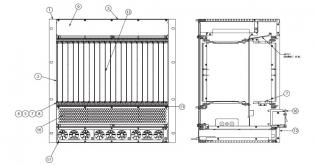

Pixus Technologies' focus allows our customers to supply the application while we provide a reliable architecture solution on time. One of our main tasks is to develop and test individual parts, then supply these fully assembled and tested in any required configuration and quantity. The modular concept of our subracks permits a wide range of applications with the minimum number of components, since they are based on the same horizontal rails and system components. The only difference lies in the design of the side panels and configuration variants. Equipped with a backplane and power supply, a standard subrack can be rapidly upgraded to an Integrated System, for example. The subracks are shock and vibration-tested and conform to the latest IEC and IEEE specifications.

Pixus Technologies offers expert advice in the implementation of mechanical design for the production of electronic chassis. Pixus mechanical engineers provide a complete range of mechanical design services in partnership with the expertise and world class production facilities of Rittal. Pixus mechanical engineers also carefully consider the thermal implications of the design and work closely with thermal engineering to ensure the product will perform in its intended application. Pixus Technologies works with clients to simulate and test the real-life environmental factors of the application and make the necessary adjustments to maximize performance.

Thermal Simulation

Using thermal analysis software and test equipment, Pixus is able to provide thermal management analysis of the enclosures. We can perform "what if...?" simulations to determine the best course of action in providing adequate cooling while balancing your EMC, acoustic noise, mechanical, and cost-basis requirements.

Contact Pixus to discuss your thermal simulation/testing needs.

Backplane Simulation/Characterization

Pixus Technologies can perform pre-design simulation and post-design characterization testing to confirm superior backplane performance.